Covering Preparations

I used Poly Fiber products as that is what I had experience with. I will not go into a lot of detail here as the web is full of information about how to do this. The Poly Fiber Manual is indispensable and should be studied thoroughly. YouTube.com and the EAA web site is full of good stuff. There has been some really good work done with latex paints. I chose not to go that route but after seeing it first hand, I would consider it.

Check out WienerDogAero for more on latex painting.

Poly Fiber products are expensive and you need ventilation and some equipment. Latex is way less money, but takes a lot more time and effort. You have to decide which is right for you.

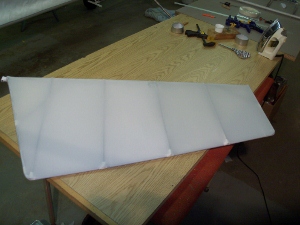

The Firefly kit calls for 28 yards of fabric. I ordered 30 and had about a yard left over. The extra 2 yards is not very expensive if you order it right away and it eliminates the worry of running out.

I had old fabric from another project and made up several test frames to practice on and did a shrink test at various temperatures. Calibrate your iron first!