First Parts Added

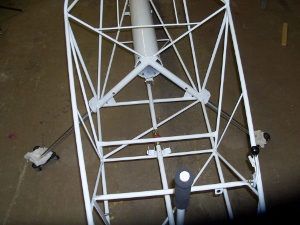

Gear legs are installed. No wheels yet as they were direct shipped from that supplier. The gear legs are resting on some little dollies so I can push it around the shop.

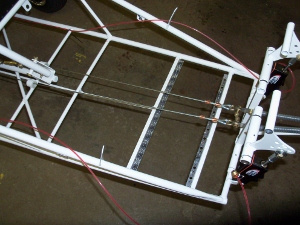

Joystick and aileron torque tube. The sealed U-joint sure makes it easy.

Throttle and choke levers are installed.