Wings On!

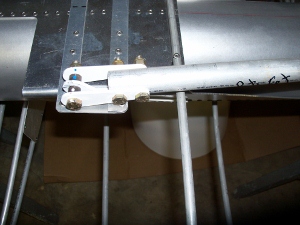

At this point the wings needed to be installed so that the aileron push tubes could be rigged.

The shop is 30' wide at the floor, but the sloping walls quickly narrow it down. Fortunately the Firefly fits with a little room to spare. However, there is so much other "stuff" in my shop, there was no room to fold the wings. That would have to wait until it was assembled outside.